Engineering

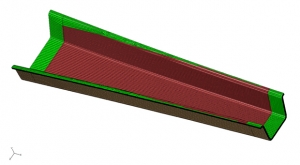

The starting point for the finite element analysis is a rectangular heating panel.

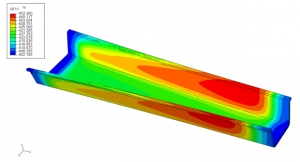

The starting point for the finite element analysis is a rectangular heating panel. Inhomogeneous distribution of heat by radiation, forced convection and thermal conduction.

Inhomogeneous distribution of heat by radiation, forced convection and thermal conduction. Optimisation of the heating fabric gradation by means of FE analysis.

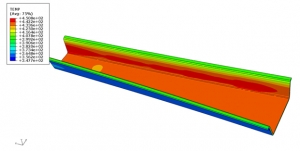

Optimisation of the heating fabric gradation by means of FE analysis. Homogeneous distribution of heat as a result.The heating kit is designed on the basis of the available data.

Homogeneous distribution of heat as a result.The heating kit is designed on the basis of the available data.

We have developed calculation algorithms for many geometries.

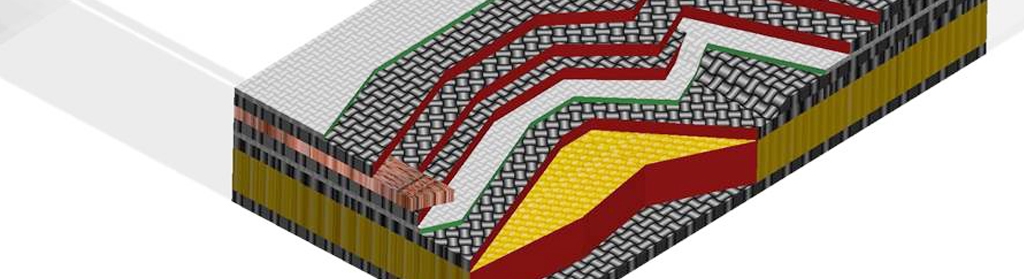

To ensure that the heating power at each point on the surface is the same, in simple terms one can say that the conductive cross section of the heating CRP layers must also be the same at each point of the mould. Width changes over the length of heating panel are compensated accordingly by varying the number of layers or by changing the fabric grammage. This is flanked by consideration that the electrical characteristic values of voltage and amperage of the heating field assume sensible ratings (Nobody wants to operate a heating field that is defined with 2V voltage and 800A current).

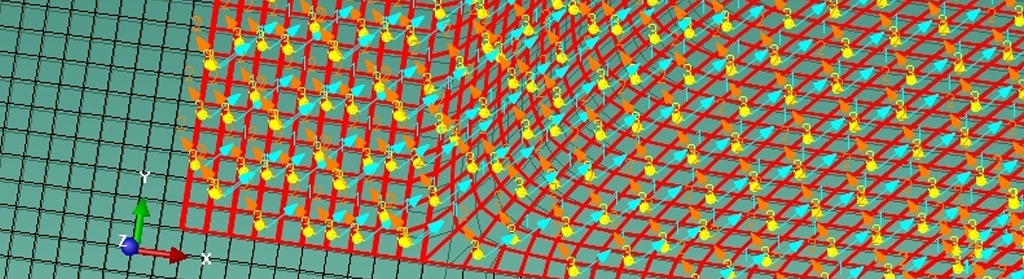

For complex geometries, in which numerical calculation methods reach their limits, we optimise the heating field design based on thermoelectric finite element analysis. In addition to the geometric influencing variables, effects such as thermal radiation between parallel walls, forced convection and heat conduction to unheated areas/capacities are taken into account.

Based on the design, a cutting and laminate pattern is derived, which defines the performance data for the hardware for heating and control, and a bill of materials with material requirements for the respective project is created.

In order to correctly evaluate the many parameters that influence the distribution of heat, in addition to calculation methodology, lot of experience in the design of carbon fibre heating is required. Trust our team as it has acquired practical knowledge in this field over many years.