Deutsch | English

Heating control / Monitoring

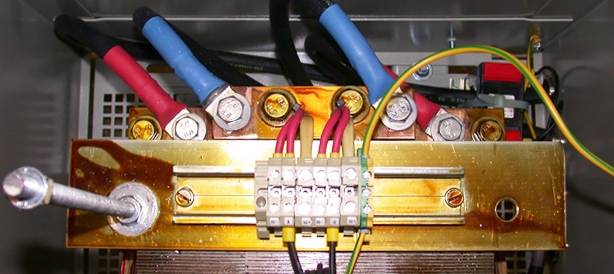

Electrical energy is required for operating the CRP heating. The use of carbon fibre fabric for the resistive heating makes fibretemp® moulds have generally low electric resistance (Ri<1Ω).

This results in an operation at low voltage (U0< 42V). A switched-mode power supply or a transform is used for generating low voltage.

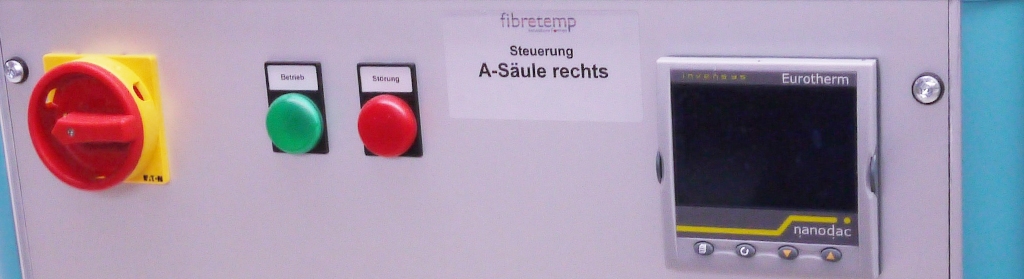

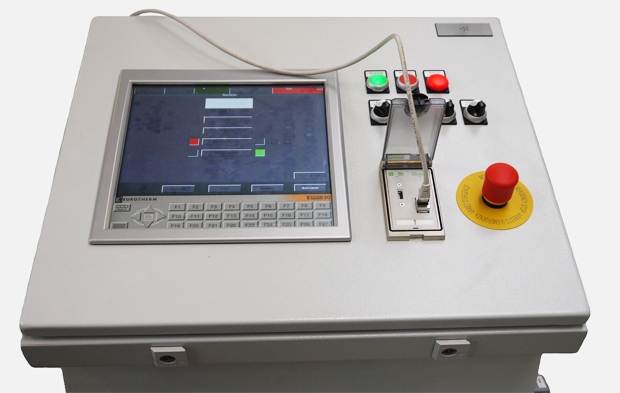

The temperature control of the moulds is done as standard via temperature sensors and thermocouples (Pt100, type K or J), which in conjunction with the process controllers, offer a wealth of functionalities:

The temperature control of the moulds is done as standard via temperature sensors and thermocouples (Pt100, type K or J), which in conjunction with the process controllers, offer a wealth of functionalities:

- Programming of the heating rate

- Programming of hold times and ramps

- Storing of diverse mould recipes

- Trimming curves for offsets between the temperature sensor and surface

- Mean value-control from several temperature sensors

- Integration of temperature monitors for protection of the tools

- Fault messages in the event of sensor damages and temperature deviations

- Recording and document management of the heating processes

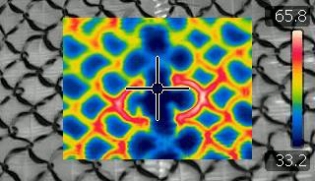

In addition to this, we offer you integration of further sensors into the mould tool for on-line process monitoring. For example, to detect flow fronts or dielectric checking of the degree of curing.