How it works

Carbon fibres are electroconductive. However, their conductivity is much lower than that for metalic materials such as aluminum or copper. This makes the fibres interesting for heating technology applications.

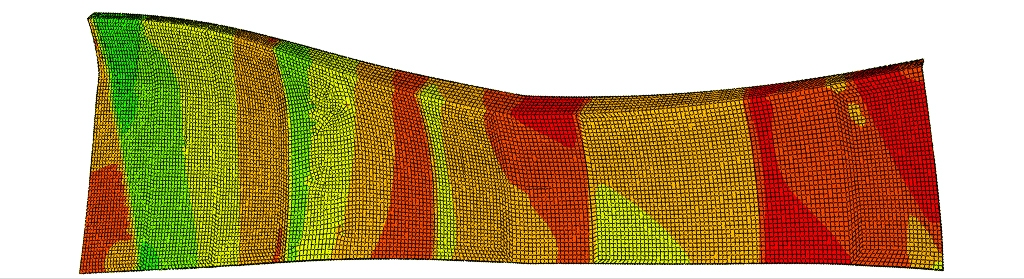

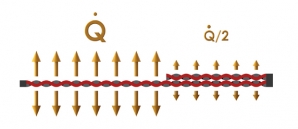

Uniform heating power in a rectangular heating panel.

Uniform heating power in a rectangular heating panel.

Reduced heating power by increasing the conducting cross section in the doubled up portion.

Reduced heating power by increasing the conducting cross section in the doubled up portion.

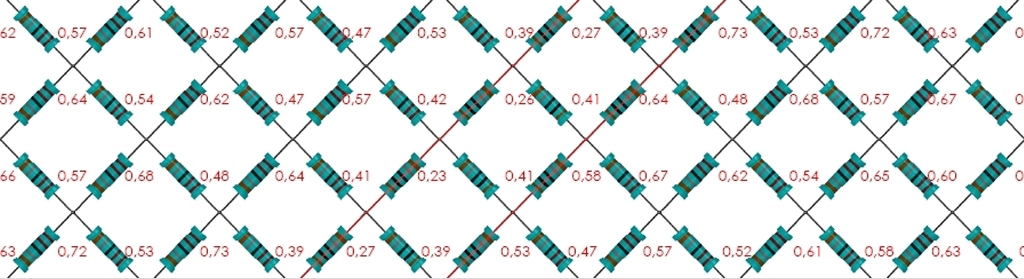

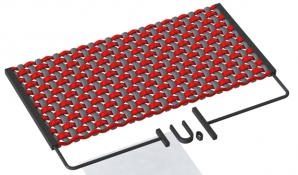

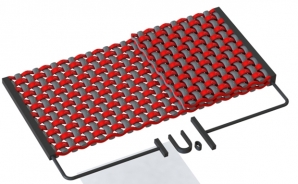

By applying an electric potential they can be used as a heat source in resistance heaters. For lossless introduction of the electric current into the carbon fibre fabric, a special fibretemp® contacting strip is inserted at the beginning and at the end of a heating panel in the fibre structure. The current flows from there in the direction of the fibre from the beginning to the end of the heating panel.

Heat is generated through the electric resistance of the carbon fibres.

The fibre fabric which are transverse to the direction of current flow provides for equipotential bonding. This has a positive influence on the reliability and robustness of the heating. The fibres extending below 90° to the direction of current flow ensure that in case of damage of a live roving, only the discrete area of the damage remains "cold".

Due to the number of individual parallel rovings, the heat generation is very uniform. Macroscopically, a panel heating is created.

The parallel circuit yields a ΔU = 0, shorts are thus avoided.

By varying the powered carbon fabric layers, individual heating powers can be realised; customised heating elements can be created.

For example, through partial doubling of the fabric layers, the resistance in these areas is lower and the heating power is reduced.